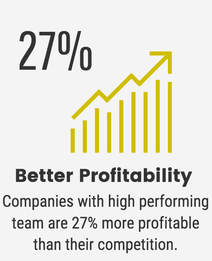

Operational Excellence is one of those terms that can have a wide variety of meanings depending upon who you speak with. For one group it is about streamlining processes. For another, it is about developing and tracking key operational metrics. And for others, it is about developing an "engaged" workforce that can spot and adjust to necessary changes quickly. I am sure you have your own unique understanding of what operational excellence is and what it means to your group. The fact is that all of these things are correct. Operational excellence is a dynamic blend of organizational design, process improvement, the development and use of metrics, continuous improvement, performance management, and employee engagement. Key though, to all of it is that really great Operational Excellence factors in the Hu (Human Element). This interesting blend of approaches is indeed dynamic and the unique ratio of each of these elements will reflect your company, it's culture, and what it needs. What is not dynamic and what is not up for interpretation is the purpose of operational excellence. Improving profitability. This can mean "becoming" profitable, increasing your profit margins, ramping up a competitive advantage, increasing client satisfaction, increasing quality - you get it - and the list goes on. All of these goals have their nexus around increasing profits. Some Examples Let's look at a couple of examples; one that was pretty straight forward with an immediate outcome. And a second scenario that took a bit more time but with pretty spectacular outcomes as well. We Need To Free Up Budget Room Now! Company A was in the advanced stages of implementing operational excellence into its field workforce when it suddenly realized it needed some pretty drastic and immediate savings around its Op-Ex budget. Gains were beginning to come in from the field but this was a bigger and more immediate issue. A team of facilitators was brought in and various components of the company came together to spend the day brainstorming. Breakout rooms were created for teams that had representation from each department that touched production from start to finish. I facilitated one team and had them create a process map from when they came into the picture to when they handed it off. It all went up on one wall and for the first half of the meeting, it was just each department mapping their part of the process. In the second half of the meeting, each group described their process and needs until all had presented. Then the magic happened. For many of them, this was the first time they saw the process in detail from start to finish, and questions and ideas began to percolate and flow. By the end of that session, they had come up with a pretty extensive list of potential operational savings. I won't say that every item was approved but that session generated literally millions of dollars in savings! Law of Unintended Consequences Company B wanted to get field operations to learn to use performance metrics to drive day to day activities. For the executive, it was really about developing a more detailed data set to stay in front of needs and issues. We took it a bit further by teaching the frontline leadership to not only get their crews to develop their own metrics but to use those metrics to drive performance and innovation for their teams. In a short span of time crews increased performance by over 40% (based on their own metrics), downtime virtually disappeared and it was not uncommon to have more "perfect days" each month than days with issues. Crew engagement went up and client satisfaction soared! And oh yes, they collected so much valuable data that clients were now coming to them to use it. One of the unintended and pleasant side effects of this improvement was the awarding of several very high-value contracts (over $100M) with clients that only months before were considered well beyond the group's reach! Necessity is The Mother of Invention Two different companies, two different applications of operational excellence yet very similar outcomes in terms of impact on profit. Two things I want to make note of is that first of all key in both scenarios' was the involvement and work of the people in the process. The other thing I have come to notice is by the time I get called in the pain is unbearable for these companies. In desperation they look for answers they would not normally have considered. I guess necessity truly is the mother of invention! My question for you is simply this; why wait? Operational excellence is something any company can implement and it works! Performance Leadership - Think About It! Comments are closed.

|

Archives

January 2021

|